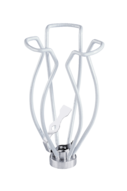

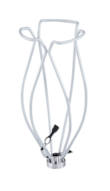

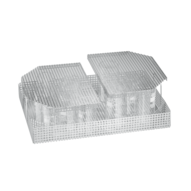

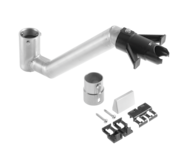

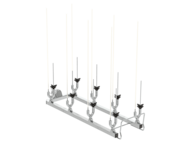

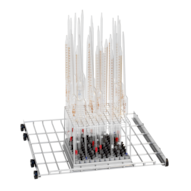

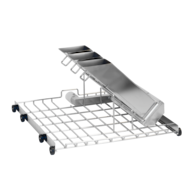

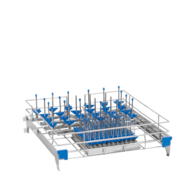

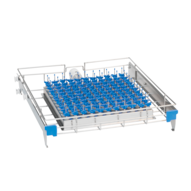

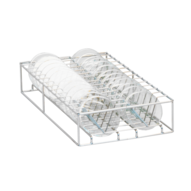

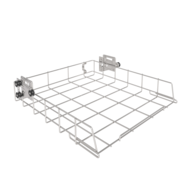

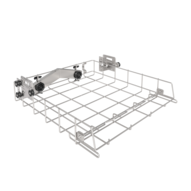

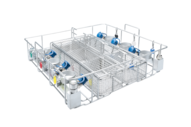

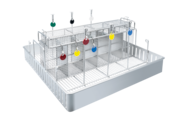

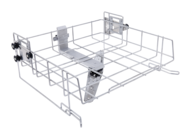

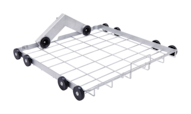

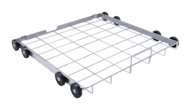

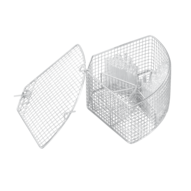

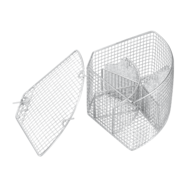

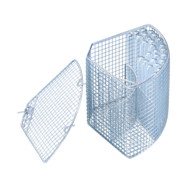

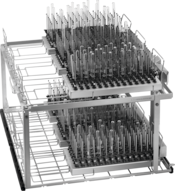

Accessories

Safe reprocessing with a focus on value retention: Versatile accessories ideally complement glasswashers in a wide range of applications.

Gift of 40 tablets

Receive 40 tabs of ProCare Shine detergent for free with the purchase of a ProfiLine dishwasher.

The free gift will be automatically applied in the basket.

Time to SAVE

We Always Increase the Quality. We Sometimes Reduce the Price.

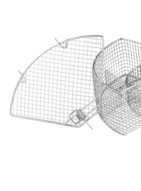

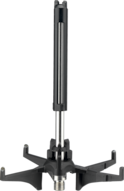

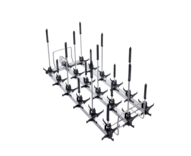

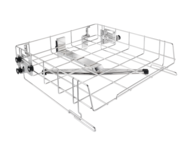

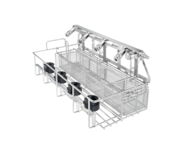

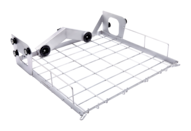

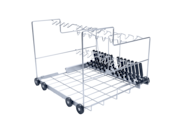

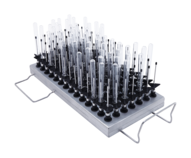

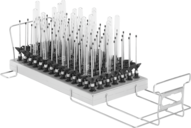

Safety machines for the fire brigade

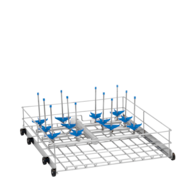

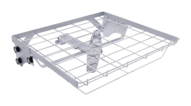

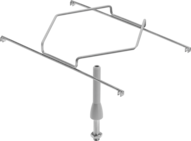

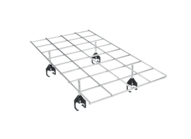

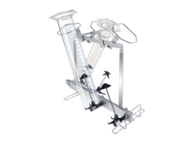

Our solutions facilitate reprocessing of breathing apparatus that is as thorough as it is gentle on materials. Our safety machines ensure the reliable positioning of masks and air regulators in the wash cabinet with carefully coordinated programmes and suitable baskets and inserts.

Our solutions facilitate reprocessing of breathing apparatus that is as thorough as it is gentle on materials. Our safety machines ensure the reliable positioning of masks and air regulators in the wash cabinet with carefully coordinated programmes and suitable baskets and inserts.

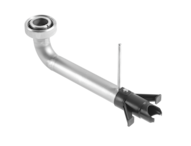

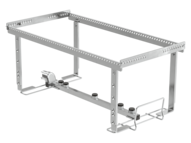

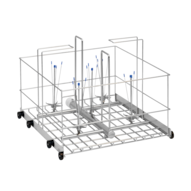

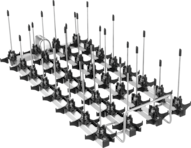

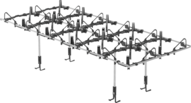

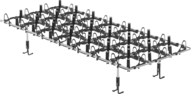

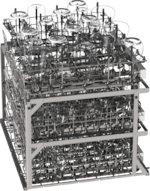

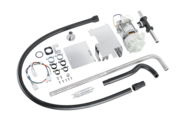

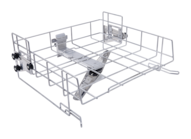

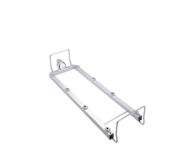

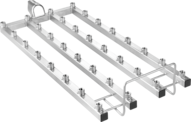

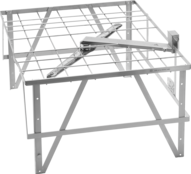

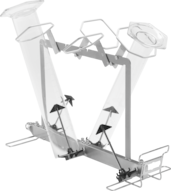

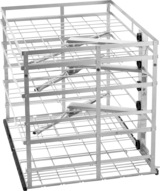

Large-capacity safety machines for fire brigades

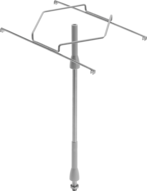

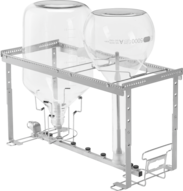

Our large-capacity safety machines delivers both reliable hygiene and high process reliability when reprocessing breathing apparatus. Thanks to the larger capacities and extended equipment options, compressed air unit carrier frames and compressed air bottles can also be reprocessed.

Our large-capacity safety machines delivers both reliable hygiene and high process reliability when reprocessing breathing apparatus. Thanks to the larger capacities and extended equipment options, compressed air unit carrier frames and compressed air bottles can also be reprocessed.

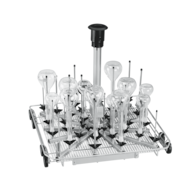

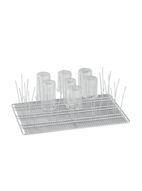

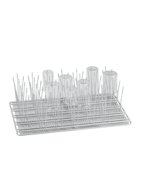

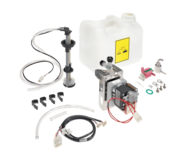

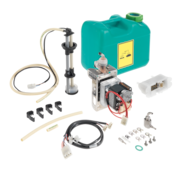

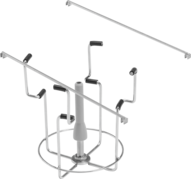

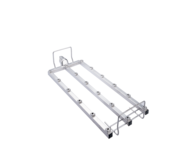

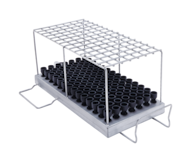

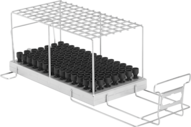

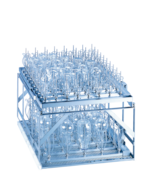

Learn more about our accessories for laboratory washers

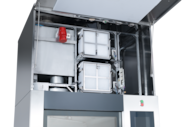

360PRO for your laboratory

Taking care of everything

With 360PRO Miele Professional offers a comprehensive package of solutions for the effective and economical reprocessing of laboratory glassware. Based on many years of experience and developed in close consultation with experts in the field, our solutions cover all the major aspects of reprocessing: powerful machines, perfectly integrated process chemicals, nationwide customer service and comprehensive advisory service by experts in our in-house application laboratory. Technology and know-how come from the same source and therefore are perfectly integrated with each other. The result is an analytically pure, particularly seamless, gentle and economic reprocessing process. And administration time is optimised too, since Miele is always at your side as an expert partner in all matters – from machine technology to planning and financing.